One of the primary challenges facing the automotive and heavy-duty industry is the growing complexity of regulatory restrictions, more so around emissions standards. With regulations such as CARB (California Air Resources Board), the United States Environmental Protection Agency, and many others, companies face a labyrinth of legal requirements to ensure compliance. The granularity of these regulations is only increasing, with distributors and retailers facing restrictions at the state and even county levels. For example, the legal ability to sell your products can vary depending on the specific location, including the brick-and-mortar address and the shipping destination, which calls for a more sophisticated approach to data management.

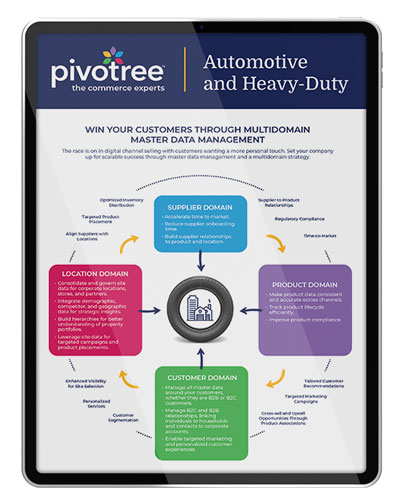

A multidomain master data management (MDM) system can significantly help companies in the automotive and heavy-duty industries navigate the growing complexity of regulatory restrictions. By creating a centralized, unified view of critical data across multiple domains—such as products, customers, suppliers, and locations — multidomain MDM ensures consistency, accuracy, and accessibility of information vital for meeting regulatory requirements. Here are the 7 key ways multidomain MDM can make a difference:

1. Centralized Compliance Data

With regulations varying across regions, a multidomain MDM system enables companies to maintain a single source of truth for compliance-related data across all geographic markets. It centralizes documentation for emissions standards, safety protocols, certifications, and industry-specific requirements, ensuring teams worldwide have access to up-to-date information. This reduces the risk of missing critical updates or misinterpreting local regulations.

2. Streamlining Reporting Processes

Many regulatory regulations require ongoing reporting to authorities. A multidomain MDM system can automate the collection and organization of data needed for these reports, ensuring that it is complete, accurate, and readily accessible. For instance, data on vehicle emissions, safety tests, and materials used in manufacturing can be structured and formatted for easy retrieval, saving time and reducing errors in reporting.

3. Improved Data Accuracy and Consistency

In industries where regulations are complex, data that is inaccurate or inconsistent can lead to non-compliance. A multidomain MDM system ensures data accuracy by eliminating silos across departments (e.g. engineering, manufacturing, legal) and synchronizing information in real-time. This consistency reduces discrepancies in compliance documents and ensures that the entire organization works from the same verified data set.

4. Supporting Traceability and Auditing

Regulatory bodies often require traceability of parts and components, particularly when dealing with safety recalls or quality control issues. Multidomain MDM helps companies maintain a complete audit trail by linking product data with supplier information, production records, and regulatory certifications. This makes it easier to track the origin and life cycle of components, demonstrating compliance and enabling rapid responses to audits or investigations.

5. Facilitating Cross-Domain Collaboration

Regulatory compliance impacts multiple areas, including product development, supply chain management, and customer support. A multidomain MDM system facilitates collaboration by connecting data across domains like product specifications, supplier information, and geographic regulations. This integrated view allows teams to work together more efficiently, ensuring that compliance considerations are embedded in every part of the business process.

6. Adaptability to New Regulations

As regulatory requirements evolve—whether it’s due to new environmental policies or safety standards — multidomain MDM systems can be updated to reflect these changes across all domains and ensure companies can quickly adapt to new rules without disrupting operations. Automated workflows and notifications can alert relevant teams when new compliance actions are required, reducing the risk of falling behind.

7. Reducing Costs and Risks

By ensuring accurate data management and efficient compliance processes, a multidomain MDM system reduces the potential for fines, delays in product launches, or costly re-engineering of products to meet regulatory standards. It also minimizes the risk of operational disruptions due to non-compliance, providing long-term cost savings.

Hit all the Green Lights with Multidomain-Driven Compliance!

A multidomain MDM system simplifies regulatory compliance by centralizing and synchronizing critical data, enabling accurate reporting, enhancing collaboration, and improving adaptability. For automotive and heavy-duty industries, where compliance is paramount, multidomain MDM provides a robust framework to navigate regulatory demands while minimizing risks and optimizing operational efficiency.

Pivotree multidomain Master Data Management (MDM) solutions streamline data governance across all domains—ensuring consistency, accuracy, and compliance with the latest industry regulations. Whether you’re an automotive manufacturer or a heavy-duty equipment firm, Pivotree’s tailored MDM strategies provide a robust framework for managing product information, supplier data, and customer records. Partner with Pivotree to meet compliance standards, drive operational efficiency and innovation in your organization.

SAM RUSSO

Practice Director, Automotive and Heavy-duty Industry

Sam has 18 years of automotive industry experience. She is a trailblazer for data management in the industry and actively contributes to the Auto Care Association’s Technology Standards Committee. With an IT and fine arts background, Sam has held roles in product management, data management, and software engineering, providing her with holistic knowledge and a unique perspective. She is also part of the ACPN Leadership Committee and the MEMA Business Technology Council. Sam is a proud mom and shares her automotive passion with her husband, who also owns an automotive shop.